Cellophane & BOPP Wrapping Machine Desktop Packaging Machine Perfume cosmetic box Play Card Blister Film Packaging

Cello Wrapping Machine

Manual Cellophane Wrapping: A Step-to-Step Guide

A manual cellophane box wrapping machine, also called a cello wrapping machine, is a versatile and in-demand packaging method. It is used widely in numerous industries for its appealing appearance and protection. Whether you are wrapping perfume boxes, cream boxes, or getting ready gifts, cellophane wrap gives a sleek, professional finish that can make any product appear more attractive. This tutorial will discuss the benefits, process, and best practices of hand cellophane wrapping and the supplies, including clear cello wrap and precut cellophane sheets.

1. What is Cellophane Wrapping?

Cellulose, a natural ingredient extracted from plants, is the composition of cellophane paper that has been confused with plastic. This makes it a biodegradable product that can compete with plastics. Cellophane wrap has been used for over a century and is still widely used in packaging products, mainly in wrapping items where appearance matters, such as perfume boxes and cream boxes.

While automatic machines are applied to large-scale operations, hand cellophane wrapping is an excellent alternative for small businesses, personal projects, or any scenario in which flexibility is needed. Be it gift wrapping or retail product preparation, the cost is low, but the personal touch is very high with manual wrapping.

2. Why Manual Cellophane Gift Wrap?

There are several reasons why manual cellophane gift wrap is preferred for small-scale packaging.

Cost-effective: Small businesses or individuals cannot afford expensive wrapping machines. Wrapping by hand is cost-effective, yet professionally finished.

Environmentally Friendly: Cellophane paper is biodegradable. This means that, over time, it breaks down naturally. It’s an environment-friendly choice for companies looking to reduce their environmental footprint.

Presentation is Key: Clear cellophane wrap makes the product beautiful yet allows for the inside product to be seen, and the gloss, polished look appeals to gift packaging and at point-of-sale.

Adaptable: Hand-wrapping accommodates different shapes sizes-whether a small cream box or a large gift basket.

Protection: Besides being an aesthetically pleasing way of wrapping your product, cello can also help protect it from dust, dirt, and moisture, which may keep the quality intact.

3. Supplies and Equipment for Hand-wrapping Cello

As you prepare to wrap your product, you will need the following supplies and equipment ready for you to assemble.

Cellophane Sheets or Rolls:

If you are packaging smaller items, you will find using precut sheets of Cellophane is suitable. You would do better with a roll of cellophane wrap for bigger or shaped products.

Scissors: Sharp scissors are a must for clean, straight cuts.

Clear Tape: Invisible adhesive tape is good for sealing edges without detracting from the overall appearance.

Ribbons and Bows: If you are wrapping a gift, add some finishing touches with ribbons or bows to make it look pretty.

Double-Sided Tape (Optional): This will create a seamless look if you want to avoid lines from the tape.

Optional: Heat Sealer Close the wrap professionally by securing it tightly and cleanly using a heat sealer.

How to Do Step-by-Step Manual Wrapping using Cello Wrap

These are the ways you may manually cellophane wrap your products, this time using clear cello wrap:

Step 1: Prepare Your Materials

Prepare all your materials. Whether using precut cellophane sheets or a roll of clear cellophane wrap, ensure you have enough to cover your item completely. Lay the sheet flat on your workspace.

Step 2: Cut the Cellophane

Place your item inside the Cellophane, such as a perfume box or gift. Cut as much cellophane paper as needed to allow for enough excess on all sides to cover the product.

Step 3: Place the Product

Place the product directly in the center of the Cellophane to ensure equal amounts of the wrap around all sides of the object. This will ensure almost perfectly balanced and neat packaging.

Step 4: Fold the Sides

Begin by drawing one side of the Cellophane, wrapping it over the product, and folding the other so the edges overlap. Secure the overlap with clear tape or use a heat sealer for a neater finish.

Step 5: Fold and Seal the Ends

Neatly fold the side triangles inward onto the sides of your product, and then use transparent tape or heat seal them in place.

Step 6: Embellishments

You can add bows, ribbons, and other labels using Cellophane wrapping if this is part of your gift. There are two reasons: it makes packages look fabulous and makes every single one unique.

5. Common Problems and How to Prevent Them

Even though the process of hand-wrapping Cellophane is quite simple, some common problems occur:

Wrinkled Cellophane:

To avoid wrinkles, gently pull the clear cellophane wrap tight as you fold and secure it. If wrinkles form, try smoothing them out with your hands before sealing.

Loose Edges: If the edges are not tightly stuck, double-sided tape can be used to stick them in place so that the tape lines cannot be seen.

Tearing: Cellophane paper is prone to tearing if too much force is applied. So, handle the wrap with special care while cutting or folding.

6. Uses of Hand Cellophane Wrapping

Hand cellophane wrapping is used in many sectors for various purposes:

Cellophane gift wrap can be used for holiday and birthday celebrations or special events. This will ensure that the gift looks polished and professional.

Retail packaging uses clear cello wrap to cover perfume boxes or cream boxes. The contents of these items are visible through the packaging, which is the advantage of this material.

Cellophane wrap is also used to package baked goods, candies, and other food products. This material ensures product moisture protection and visibility.

Crafts and DIY Projects:

Some people use precut cellophane sheets to craft or package homemade items, such as candles or soap.

7. Why Cellophane is an environment-friendly choice

Another good thing about the use of cellophane wrap as compared to the use of plastic is its ability to be biodegradable. Cellophane paper is cellulose-based and will decompose, meaning it is non-toxic and not a pollution source since plastic takes thousands of years to break down. Thus, this is how wrapping using Cellophane is environmentally friendly.

However, some kinds of Cellocellophane synthetic coatings make them more durable. This could reduce their biodegradable capacity. If you are looking for sustainable packaging, look for the clear, natural, uncoated cellophane wrap.

8. How to Hand Wrap Your Products Successfully with Cellophane

Use the Right Thickness: Thick cellophane paper is sturdier, while thin wraps are more convenient to use and fold. Use whichever thickness works well for your product.

Keep it Taut: The trick to a tight, professional finish is to keep the cello wrap clear and taut throughout the folding and taping process.

Take Your Time: Especially if you are a beginner, practice patience. There is a bit of trial and error in trying to get the folds right, ensure no wrinkles, and achieve a clean finish – but it’s worth all that effort.

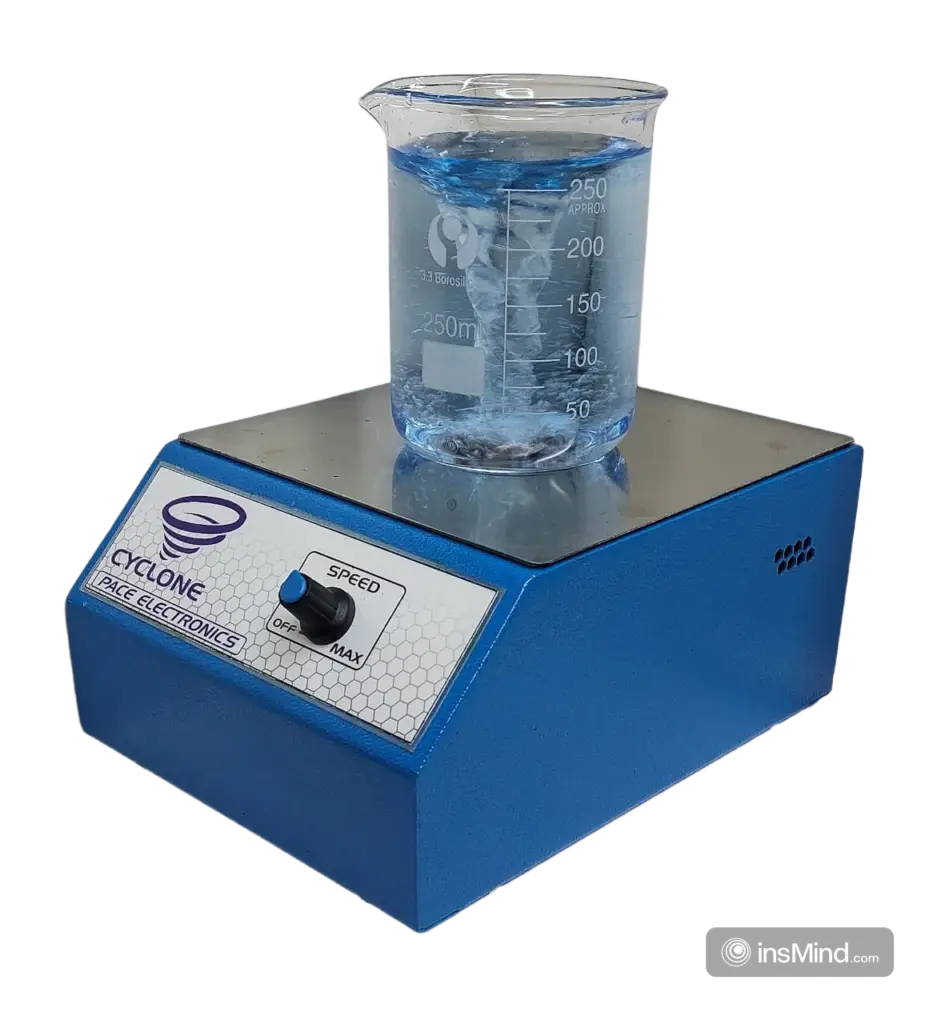

Other items that require special handling or equipment in labs include product items placed close to laboratory devices, such as a hotplate stirrer. For such applications, the use of cellophane wrap protects the item’s cleanliness while at the same time allowing visibility.

Related Products:

Magnetic Stirrer for Chemical mixing,

Hotplate Magnetic Stirrer For chemical processing,

Conclusion

The use of manual cellophane wrapping is simple yet effective. Whether you work with precut cellophane sheets or large rolls of clear cello wrap, it offers flexibility and creativity. This makes it an eco-friendly, cost-effective option for small businesses, personal projects, and special events. Cello wrapping ensures your product looks good and stays safe.

Use this guide and become an expert on manual cellophane wrapping of products or gifts that look professional and neat each time.